BITUMEN

TRUSTEE SUPPLIER OF BITUMEN 35/50, 40/50, 60/70, 80/100, ASPHALT AND SULPHUR BASE

BITUMEN 60/70

Definition of bitumen penetration grade 60/70

Penetration grade 60/70 means the penetration value is in the range 60 to 70 at standard test conditions which commonly used as a Paving Grade. This is applicable for the production of hot mix asphalt for bases and pavements and for road construction. This is produced through aeration on vacuum bottom (the raw material used for making left in vacuum distillation column in oil refineries) in production units. Its penetration grade (the measure of hardness) is between 60 to 70. Bitumen is specified by the penetration and softening point test. Designing is by penetration range only. The penetration grade has a thermoplastic property which causes the material to soften at high temperatures and to harden at lower temperatures. This unique temperature-viscosity relationship is important when determining the performance parameters such as the adhesion, durability and application temperatures.

The Bitumen mode is dependent on temperature. The temperature-vs-stiffness relationship of this is dependent on the type of crude oil and its refining method. Bitumen penetration grade 60/70 is semi-hard penetration grade This is used as a paving grade which is suitable for road construction and repair. It is also used for the production of asphalt pavements with the below technical specification. This grade of bitumen is mainly used in the manufacturing of hot mix asphalt for bases and wearing courses. 60/70 is one of the most used bitumen grades and it’s a basic material for all other bituminous products.

Penetration determines the hardness of bitumen by measuring the depth to which a standard loaded the needle will vertically penetrate in 5 seconds, in a sample of bitumen maintained at a temperature of 25 degrees Celsius.

Application of bitumen penetration grade 60/70

Bitumen 60/70 is suitable for road construction and for the asphalt pavements with superior properties. This type used in the manufacture of hot mix asphalt for bases and wearing courses and the main usage of this product is used in the road in mild regions. The bitumen is provided during the presses of oxidation of vacuum bottom in bitumen production units. Due to its medium air blowing and penetration, it is used in mild areas.

Bitumen is a product of Crude Oil Distillation. It is a semi-solid hydrocarbon product produced by removing the lighter fractions (such as liquid petroleum gas, petrol and diesel) from heavy crude oil during the refining process. As such, it is correctly known as refined bitumen.

“ASPHALT CEMENT” or “ASPHALT”

In North America, bitumen is commonly known as “Asphalt Cement” or “Asphalt”. While elsewhere, “Asphalt” is the term used for a mixture of small stones, sand, filler and bitumen, which is used as a road paving material. The asphalt mixture contains approximately 5% bitumen. At ambient temperatures bitumen is stable, semi-solid substance.

HISTORY OF BITUMEN

The Sumerians also used it as early as the third millennium BCE in statuary, mortaring brick walls, waterproofing baths and drains, in stair treads, and for shipbuilding. Other cultures such as Babylon, India, Persia, Egypt, and ancient Greece and Rome continued these uses, and in several cases the bitumen has continued to hold components securely together to this day. In some versions of the Book of Genesis in the Bible, the name of the substance used to bind the bricks of the Tower of Babel is translated as bitumen. Although its existence has not been confirmed, a one-kilometer tunnel beneath the river Euphrates at Babylon in the time of queen Semiramis (c.a. 700 B.C.) was reportedly constructed of burnt bricks covered with bitumen as a waterproofing agent. The term bitumen comes from Latin. The Greek name for the substance was ?σφαλτος (asphaltos). Approximately 40 A.D. Dioscorides described production of asphaltos (as distinguished from piss asphalt and naphtha): (1655 Goodyear translation). The terms asphalt and bitumen are often used interchangeably to mean both natural and manufactured forms of the substance. “The Judaicum Bitumen is better than others; that is reckoned the best, which doth shine like purple, being of a strong scent & weighty, but the black and fowle is naught for it is adulterated with Pitch mixed with it. It grows in Phoenice also, and in Sidon, & in Babylon, & in Zacynthum. It is found also moist swimming upon wells in the countries of the Argentines of Sicily, which they use for lamps instead of oyle, and which they call falsely Sicilian oyle, for it is a kind of most Bitumen. The Judaicum Bitumen is a famous deposit of native asphalt seeping through diapirs at the bottom of the Dead Sea, which comes occasionally to the surface through seismic activity in blocks of up to 100 tons in weight which are more than 99.99% pure. It was the object of the first known battle for a hydrocarbon deposit, between the Seleucids and the Nabateans in 312 B.C.

GEOLOGICAL ORIGIN OF BITUMEN

Naturally occurring deposits of bitumen are formed from the remains of ancient, microscopic algae and other once-living things. When these organisms died, their remains were deposited in the mud on the bottom of the ocean or lake where they lived. Under the heat and pressure of burial deep in the earth, the remains were transformed into materials such as bitumen, kerogen, or petroleum. Deposits at the La Brea Tar Pits are an example. There are structural similarities between bitumen and the organic matter in carbonaceous meteorites. However, detailed studies have shown these materials to be distinct. Given that analogous matter is found in certain meteorites and bitumen are also found in Archean rocks it is possible that some bitumen are primordial material formed during accretion of the Earth and reworked by bacteria that consume hydrocarbons.

BITUMEN APPLICATION

Known for its adhesive and cohesive assets, bitumen is mostly utilized in the construction industry. Bitumen is applied on road paving because it is viscous when hot, but solid once it cools down. Therefore, Bitumen operates as the binder/glue for pieces of the aggregate.

The vast majority of refined bitumen is used in construction: primarily as a constituent of products used in paving and roofing applications. According to the requirements of the end use bitumen is produced to specification. This is achieved either by refining process or blending.

It is estimated that the current world use of bitumen is approximately 102 million tonnes per year. Approximately 85% of all the bitumen produced is used as the binder in asphalt for roads.

Bitumen is applied in construction and maintenance of:

- Highways

- Airport Runways

- Footways / Pedestrian Ways

- Car Parks / Race Tracks

- Tennis Courts

- Roofings

- Damp Proofing

- Damp Reservoir & Pool Linings

- Sound Proofing

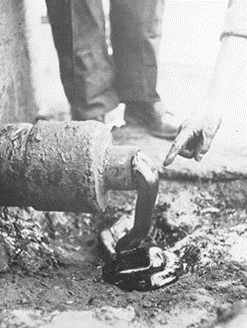

- Pipe Coating

- Cable Coating

- Paints, Building Water Proofing

- Tile Underlying Water Proofing

- Newspaper Ink Production

- And many other applications

In order to realize the complexity of bitumen as a product an in-depth knowledge and detailed understanding for one of the way the roads are built is crucial. Specialists in bitumen know bitumen as an advanced and complex construction material, not as a mere by-product of the oil refining process. The ultimate paving material (also referred to hot mix asphalt concrete – HMAC or HMA) consists of about 93 – 97% mineral aggregate (stone), sand and filler. The remaining percentage is bitumen.

BITUMEN PRODUCTION PROCESS

Of the wide variety of crude oils commercially available, only a limited number are considered suitable for producing bitumen of the required quality in commercial quantities. In general, these are heavy crude oils with a high Sulphur content.

In modern, integrated refineries, it is common practice to blend multiple crude oils to produce consistent quality high grade bitumen that meets precise engineering specifications.

Production processes

Residues from the distillation of meticulously selected crude oils provide the base materials for bitumen production. Bitumen refining separates the lighter fractions from the residues. Several manufacturing methods are used to produce specification bitumen depending on the crude source and processing capabilities available. Often a combination of processes is selected. The illustration shows a compilation of the main refinery processes employed.

Distillation

The most common refining process is straight reduction from crude or a crude blend, using atmospheric and vacuum distillation. In the diagram, atmospheric distillation is used to separate lighter petrochemical and fuel fractions from the non-boiling component at the bottom, known as an atmospheric residue. The lighter fractions, such as gas oil and fuel oils are fed to other refinery units. The atmospheric residue is retained for bitumen. To remove the last traces of the lighter fractions and avoid heat transformation of the molecules, the atmospheric residue is introduced into a vacuum distillation unit, here the pressure reduction lowers boiling temperatures and unwanted thermal cracking of the molecules can be avoided.

Solvent de-asphalting

Specific solvents can also be used to separate the lubricant and bitumen components of crude, without damaging their chemical structure. According to the solvent used – propane or butane – different categories of bitumen can be obtained. Along with finely controlled variations in the vacuum distillation process, these processes permit the production of bitumen with varying levels of penetration. This property and the softening point are the two fundamental defining characteristics of bitumen produced to engineering specifications. Further key physical properties are sensitivity to temperature and ageing, cohesion and elasticity, all of which are measured by precise tests.

Oxidation

Bitumen can be further processed by blowing air through it at elevated temperatures (280°C on average) to alter its physical properties for commercial applications. Oxidised bitumen covers two distinct types depending on the degree of oxidation: air rectified and oxidised. Oxidised bitumen has a distinctive consistency at room temperature and a rubbery nature which affects how it responds to stress, or imprint. The process of oxidation increases the stiffness and softening point of the bitumen and considerably alters key physical properties. Varying the length of the oxidation or air blowing process varies the extent of the reaction and produces distinctive end products. Oxidised bitumen is used in roofing applications, while air rectified bitumen is used in paving applications and some roofing applications.

Blending

The final bitumen product can be produced to technical specification either directly in the refining process or by blending bitumens with different physical properties. Blending of higher and lower viscosity residues in the required proportions may take place at the refinery, at terminals or at a third party facility, where blend components and finished products can be easily transported and distributed for use

Standardizing Bodies

In different regions and countries, different Standards and Grading systems are used for determining the quality of petroleum bituminous Binders. The most recognized standards for petroleum bitumen are published by:

- European Committee for Standardization (CEN)

- Deutsche Industrie Norm (DIN EN)

- Association Française de Normalisation (AFNOR – NF EN)

- BSI Standards - the UK's National Standards Body (NSB - BS EN)

- American Society for Testing and Materials (ASTM)

- American Association of State Highway and Transportation Officials (AASHTO)

- South African Standard Organization (SABS)

- Standards Australia (AS)

MOST COMMONLY USED BITUMEN SPECIFICATIONS

Standard Petroleum Bitumen Grades

- ASTM D 946 and AASHTO M 20 (Penetration @ 25°C)

- ASTM D 3381 and AASHTO M 226 (Viscosity @ 60°C)

- ASTM D 6373 and AASHTO M 320 (PG-Graded Binder)

- EN 12591 (Penetration @ 25°C) → NF EN; BS EN; DIN EN; etc.

- AS 2008 (Viscosity @ 60°C)

- SABS 307 (Penetration @ 25°C; Viscosity @ 60°C after RTFOT)

- IS 73 (India) changed in 2006 from PEN grades to VG Grades (based on Viscosity @ 60°C); however, CRMB modified bitumen is still graded based on penetration)

Polymer Modified Bitumen

- ASTM D 5976; ASTM D 5840; ASTM D 5841 (based on polymer type; now outdated and not used in the USA, but still used in some developing countries)

- ASTM 6373 and AASHTO M 320 (PG-Graded Binder; applicable to Unmodified and Polymer Modified Bitumen)

- EN 14023 (Framework Standard for Polymer Modified Binder)

- AUSTROADS Framework Specifications (Australia)

Bitumen Emulsions

- USA Anionic Emulsions: ASTM D 977 and AASHTO M 140

- USA Cationic Emulsions: ASTM D 2397 and AASHTO M 208; Polymer Modified Cationic Emulsion: AASHTO M 316

- Europe: Harmonized Framework Standard EN 13808 for Cationic Unmodified and Polymer Modified Emulsions; many different national

- Annexes. (Note: Internationally there exist a very broad range of emulsion specifications; many of them are technically inaccurate and confusing.)

Cutback Bitumen

- ASTM D 2026, D 2027 and D 2028 for Slow, Medium and Rapid Curing Cutback

- AASHTO M 81, M 82 for Rapid and Medium Curing Cutback

- EN 15522 Cutback and Fluxed Bituminous Binder

TYPES OF BITUMEN

Penetration Grade

ASTM D 946 40/50, 60/70, 80/100

BS EN 12591 35/50, 50/70, 70/100

The penetration grading system was developed in the early 1900s to characterize the consistency of semi-solid asphalts. Penetration grading quantifies the following asphalt concrete characteristics:

Pentration Grade Bitumen is Bitumen classified using the penetration property. Penetration grading’s basic assumption is that the less viscous the asphalt, the deeper the needle will penetrate. Bitumen which is produced during the process of oxidation of vacuum bottom (the Bitumen production feedstock that derives from distillation tower residue in vacuum oil refineries) at bitumen production unit in a manner that its penetration point (kind of test to indicate the hardness of bitumen) in specified group is classified in different grade of Bitumen.

Penetration Grade Bitumen is commonly used in road surfacing, and some industrial applications. Additional processing yields other grades of bitumen products and their application.

PAYMENT TERM: TT & LC payments.

TYPE OF PACKING: Packing Drums (180 KG Net / 190 KG Gross Weight).

Also for some markets, specially for Bangladesh market drums of 150 KGS Net is available.

Jumbo bags (1 MT Weight), during the cold seasons loading in 20 ft containers and during the hot seasons loading in 40 ft containers.

185 KGS STEEL DRUM SPECIFICATIONS

|